Search

Preventing Costly Production Downtime in Mineral Processing

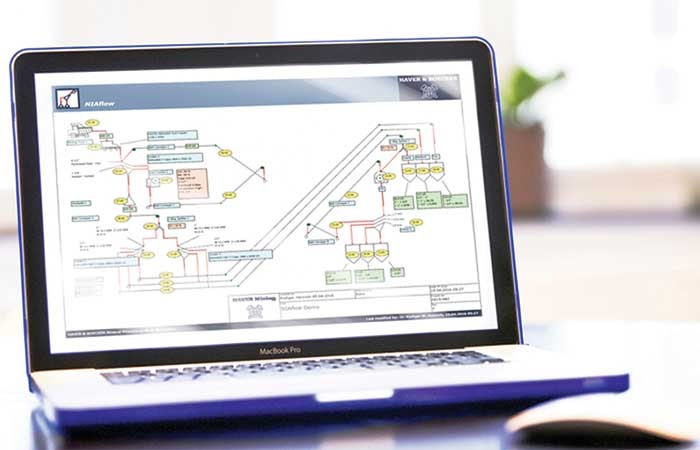

Any mineral production plant faces the challenges of maintaining the uptime of its equipment while reducing the cost of corrective maintenance.

Preventive Maintenance for Peak Productivity

Choosing a condition monitoring system to minimise downtime and maximise ROI, writes THIAGO HENRIQUE BUOSO.

Haver & Boecker Niagara showcases latest solutions at AGG1

Haver & Boecker Niagara, a leading manufacturer of screening, pelletising and mineral processing plants and systems, highlighted its latest screening equipment, technology and solutions for the aggregates industry at the 2024 Aggregates Academy & Expo (AGG1) show.

Haver & Boecker Niagara opens new service centre in Brazil

The facility provides service and support for mining operations

Bulk material handling equipment for steel & mining industry

Bulk material handling equipment plays a very important role in metals, mining, and related industries to ensure safe and efficient operations.

Living on the Cutting Edge

Wilm Schulz of Haver & Boecker writes on embracing diagnostics technology to maximise plant productivity.

Living on the Cutting Edge

Wilm Schulz of Haver & Boecker writes on embracing diagnostics technology to maximise plant productivity.

The crushing equipment industry has reached its peak.”

Titan Crushing Equipment is focused on the aggregate and infrastructure industry. The company designs and manufactures equipment under the brand name – Diamond Crushers. The company specialises in producing jaw crusher, which is widely used in mining, quarry, and material handling. Over these years, the company has gathered specialists and experience in designing and manufacturing various models of jaw crushers.

Don’t Compromise on Vibrating Screen Health

How partnering with a technical OEM for equipment monitoring can help the bottom line.

Propel bags ‘Emerging CE Company of the Year 2021’

Propel was awarded at the 9th Equipment India Awards.

V Senthilkumar of Propel: There are huge untapped opportunities in crushers & screens market

V Senthilkumar, Managing Director, Propel Industries, speaks on the current aggregate and M-sand production scenario, and market size for crushers and screens in India.

Haver & Boecker Niagara offers Pulse Vibration Analysis Service

Haver & Boecker Niagara’s new Pulse Vibration Analysis Service program helps operations achieve production targets and minimise unscheduled downtime

Haver & Boecker Niagara announces new dealer

The company will service coal mines throughout Ohio, Pennsylvania, Virginia, West Virginia and Kentucky.

Portable plant increases production by 25 per cent

Haver & Boecker Niagara, Haver & Boecker's new mineral processing brand, offers the Niagara F-Class portable plant.

Haver & Boecker Niagara introduces performance check tool

Haver & Boecker Niagara, Haver & Boecker?s new mineral processing brand, introduced PROcheck, a service program dedicated to keeping customers? operations running at peak performance.

Haver & Boecker Niagara introduces performance check tool

Haver & Boecker Niagara, Haver & Boecker?s new mineral processing brand, introduced PROcheck, a service program dedicated to keeping customers? operations running at peak performance.

Haver & Boecker Niagara F-Class portable plant increases production by 25%

Haver & Boecker Niagara, Haver & Boecker?s new mineral processing brand, offers the Niagara F-Class portable plant.

Construction equipment market is back with a bang

We see an immense focus on infrastructure (roads, airports, ports, smart city projects, etc) and industrial projects.

We expect to strengthen ties with our existing customers

The industry seems to be gradually moving out of the sluggishness. The impetus of the new infrastructure projects seems to have come in at an opportune time and soon we shall see the much-needed vibrancy in this high potential industry

Crushers & Screens| High on Demand

With infrastructure and construction sector on fast-track, especially road sector, aggregate processing has become essential to support the construction activities with a matching pace.

The Road Ahead

In spite of the government's policy shift towards building four- and six-lane National Highways as concrete roads, plans to construct more rural roads and coastal roads will drive the demand for asphalt plants in the future. EQUIPMENT INDIA explores the road ahead for asphalt plants.

Buoyant Future

An unprecedented and the highest-ever, $1 trillion has been earmarked for investment in infrastructure development by Government of India in the current Five-Year Plan period (2012-17). Speeding along the guidelines set forth by the government, the infrastructure construction activity is rapidly growing in roads and highways, bridges, airports and power, while realty sector is yet to catch up.

We plan to develop new products like jaw crushers, cone crushers and mobile plants.

We do not sell standard plants as we consider each crushing or screening task as different from the other. We aim to offer custom-built plants which will make us a cut above the others. Also, we are tapping export markets in certain areas, which keeps us busy in the present market conditions, says VP Mundra, Director, Core Crushing Equipments.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com